Description

Product: Used Cooking Oil (UCO) Vegetable Oil.

Product Overview / Key Features:

-Free Fatty Acids: 2% Max.

-M.i.u (Moisture and Impurities): 0.02 % Max

-Saponification Value: 186

-Iodine Value: 120

-Titre C (Melting Point): 13.75 C

-Total Fatty Latter (TFM): 95%

-Specific Gravity @ 25’c: 0.915

-Density (kg/m3) – 900 (min); 920

-Flashpoint by P.-M. (Degree C): 225

-Calorific Value (kj/kg): 36,000

-Kinematic viscosity (40 deg.C) (mm2/s): 38

-Carbon residue (mass-%) : 0.4

-Iodine number (g/100g) : 110

-Sulfur content: 10 ppm Max

Variable properties:

Acid value (mg Koh)/g): 2.0

Oxidation Stability (110 deg C) (h): 5.0 (min)

Phosphorus Content (mg/kg) : 15 (max)

Ash Content (mass%) : 0.01(max)

Water ontent (mass%) : 0.075 (max)

*Our Oil is fully Filtered and contains no impurities

*Packing:

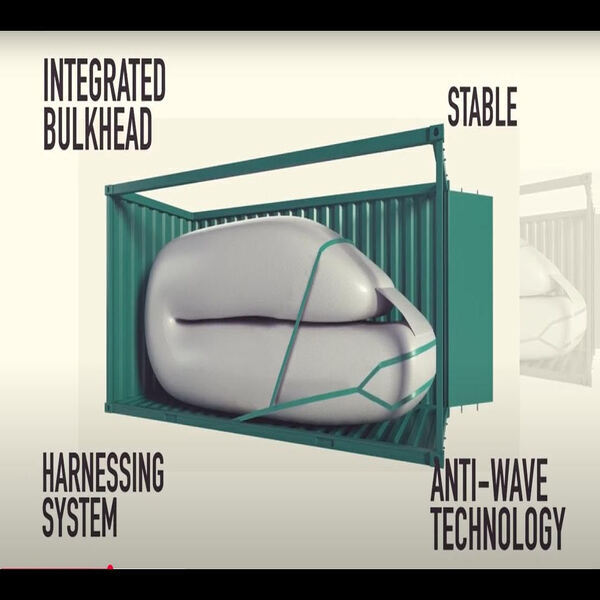

A) Flexibag inside containers, Load capacity: 27,000 Liters.

The 27,000 L capacity allows for over 12% savings on overall freight costs thanks to the increased payload

Below: Flexibag inside containers, Load capacity: 24,000 Liters.

B) 1000 Liters IBC tank, New Anti-Static IBC Steel Pallet.

C) PET Bottles 2L, 5L, 10L

D) Others Packing/ Labelling.

*Others Packing and Labelling can be adapted according to clients request.

How is cooking oil collected ?

Hundreds of used cooking oil collectors/suppliers, primarily from Europe and North Africa, are our main suppliers wherever cooking oils and fats are used. The collection of these oils is organized for recycling and reuse. Most of these suppliers are very small, as is typical in the used cooking oil sector. We draw on many small sources. Restaurants and factories store used cooking oil in tanks, which are emptied by collectors that collect used cooking oil from 55,000 restaurants, stadiums, hotels, McDonald’s, schools, and airports. It is then delivered to major distributors where filtration and quality control processes are carried out to ensure its compatibility with biodiesel production and renewable refining.

Preparing the used cooking oil for delivery/shipping.

Used cooking oil is first filtered and cleaned in pre-treatment units to remove impurities. It is then packaged and shipped to a refinery to be transformed into renewable diesel, sustainable aviation fuel, and other renewable products. At each of our sourcing sites, we have UCO-certified purchasing managers who are fully trained in the quality of these products. We also monitor our suppliers : we visit their facilities and inspect the finished product. We also perform additional checks during loading, including measuring the quality of the UCO to ensure it meets our customers’ specifications and is suitable for biodiesel production.

For each shipment, regardless of the size, a qualified independent expert issues a quality certificate, allowing us to guarantee the quality of the UCO shipped to our customers.